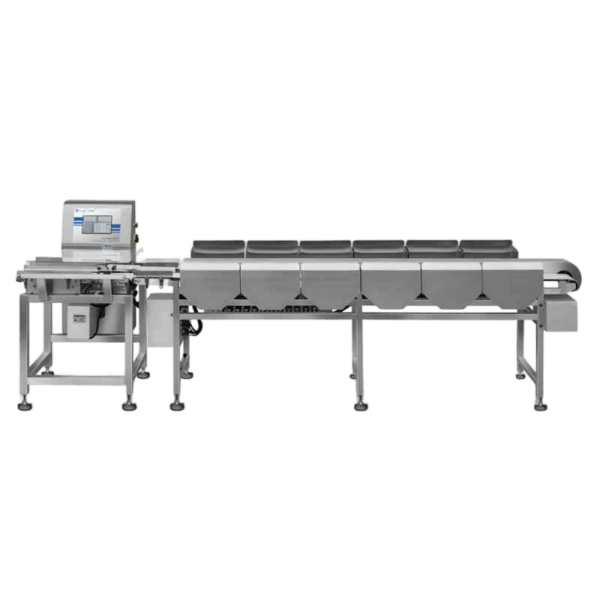

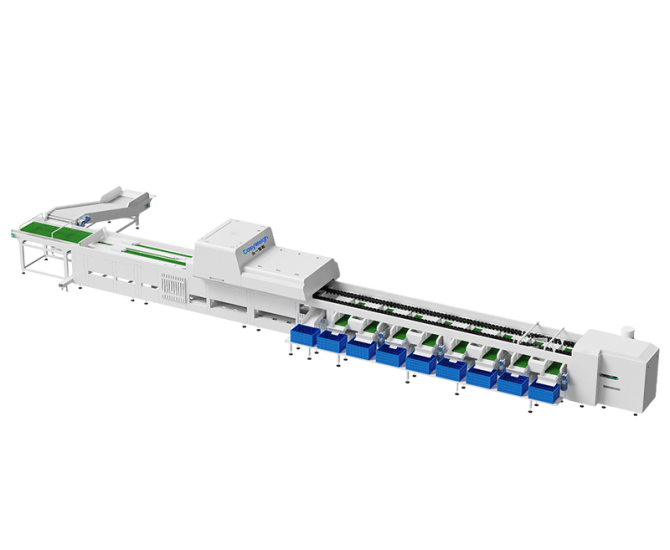

Optical Sorting Machine

The Optical Sorting Machine combines advanced imaging technology and intelligent algorithms to deliver unparalleled sorting accuracy. Capable of detecting color, size, shape, and defects, the Visual Inspection Sorter efficiently removes and substandard products from production lines. The Optical Sorter can also detect label and coding errors or omissions, and reject defective products. Designed for a wide range of industries, including food processing, agriculture, and manufacturing, this Visual Inspection Sorter ensures consistent quality while improving productivity. With user-friendly controls and customizable settings, the Vision Sorter Machine adapts seamlessly to diverse sorting needs, reducing waste and enhancing overall efficiency.