Introduction

In today’s fast-paced food processing industry, speed, precision, and accuracy are crucial for maintaining quality and meeting consumer demands. One of the key technologies enhancing efficiency and consistency in food processing is the weight grader. These sorting machines automate the classification process by sorting products based on their weight, ensuring that only items that meet specific criteria are packaged.

This comprehensive guide will examine how weight graders operate, their role in sorting systems, and how they significantly enhance overall efficiency in food processing. By utilizing advanced sorting equipment, businesses can streamline operations, reduce waste, and enhance product consistency. We will also examine how various types of food, such as fruits, nuts, potatoes, and cold shrimp, benefit from these weight-based sorting systems.

Sorting is a crucial aspect of food processing. It involves categorizing food items based on specific characteristics such as size, weight, color, shape, and ripeness. This process ensures that food products meet quality standards and are suitable for packaging, storage, or distribution.

What Is Sorting in Food Processing and Why Does It Matter?

What Is Sorting

Sorting in food processing involves the systematic classification of food items based on specific criteria. These criteria can include:

- Weight: Grading by weight helps ensure uniform portion sizes.

- Size: Fruits may be sorted according to their diameter.

- Shape: Items can be classified to allow for uniform packaging.

- Color: Ripe produce can be selected based on its color.

- Ripeness: Ripe fruits are separated from unripe ones.

By automating the sorting process, food manufacturers can achieve greater efficiency, improve product consistency, and ensure compliance with industry standards.

Why Sorting Matters

Sorting plays a vital role in the food industry for several reasons:

Maintaining Product Quality: Consistent sorting ensures that food products adhere to predefined standards for size, weight, and quality.

Regulatory Compliance: Many food categories must comply with strict packaging and labeling regulations, particularly regarding weight.

Improving Customer Satisfaction: Well-sorted products enhance consumer trust by ensuring consistency and reliability in what they purchase.

Cost Savings: Effective sorting helps reduce waste, minimize product giveaway, and optimize packaging and shipping processes.

Sorting is essential for ensuring quality and efficiency in the food industry.

How Weight Graders Enhance Sorting Efficiency in Food Processing

Weight sorting machine are necessary in a modern sorting plant. These machines are used to automatically classify products according to weight, with a number of advantages compared to manual sorting. Despite the long time that it has been available for such sorting systems, a weight grader can be used to greatly increase the speed and accuracy.

Product Placement: The food product is transferred onto a conveyor belt.

Weight System: During product travel, its weight is recorded when passes over an integrated scale. The weights are measured in units of time.

Sifting: According to the weight measured, the weight grader essays the product to the corresponding slecing bin or conveyor line. This may be done using gates, pushers or diverters.

Packaging: Goods are then sent to packing stations, where every pack is wished according to weight restrictions.

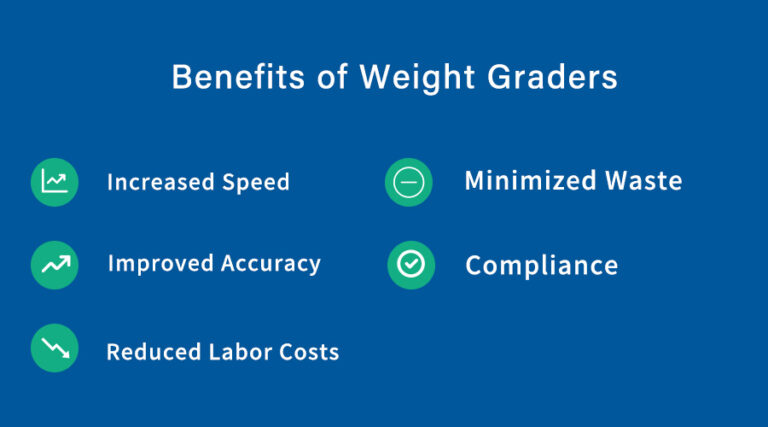

Benefits of Weight Graders

Increased Speed: Weight graders can process hundreds of items per minute, significantly faster than manual sorting.

Improved Accuracy: Automated sorting reduces the likelihood of human error, ensuring more consistent and accurate weight classification.

Reduced Labor Costs: By automating sorting, businesses can reduce the need for manual labor, saving both time and money.

Minimized Waste: Accurate sorting ensures that overweight or underweight products are identified and removed, preventing waste and improving cost efficiency.

Compliance: Weight grading ensures that products meet legal weight requirements, which is crucial for maintaining food safety and adhering to labeling standards.

Types of Weight Graders in Food Processing

Various types of weight graders and sorting equipment are used for different food processing tasks. From sorting nuts to cold shrimp sorting, these weight graders can be customized to meet the specific needs of a food processing line.

Weight Graders for Different Food Types

In fruit processing, weight grading is essential for maintaining uniformity in packaging and controlling portion sizes. Fruit sorting machines utilize weight grading to categorize fruits such as apples, oranges, and grapes into various weight classes. This process optimizes packaging and minimizes product damage during transportation.

Potato sorting machines utilize weight grading to sort potatoes by size and weight, ensuring more consistent cooking results. This process also eliminates undersized or oversized potatoes, which helps reduce waste.

Sorting cold shrimp requires precise classification by size and weight to ensure portion control for packaging. Weight graders accurately sort shrimp based on weight, minimizing waste and optimizing packaging efficiency.

Other Types of Sorting Machines

Rotating Trays Weight Grader: Integrating weight grading into hoppers enables the continuous sorting of products at high speed across different level hoppers.

Dual Lane Weight Grader: Enhance your productivity and achieve superior quality with the Easyweigh reliable Dual Lane Weight Grader. Optimize the sorting efficiency.

How Weight Graders Integrate with Sorting Systems

Weight graders are an essential part of sorting systems and do not operate in isolation. They often work in conjunction with other technologies, such as vision sorting machines and metal detectors, to ensure that products meet various quality standards. For instance, a fruit sorting machine may utilize both weight grading and optical sorting to categorize fruits based on their weight and appearance. Similarly, a potato sorting machine may integrate weight grading to ensure that each potato is the correct size for packaging.

These automated sorting machines are connected to conveyor line sorting systems, enabling a seamless flow of products from one machine to the next. This integration enhances operational efficiency by minimizing the need for manual interventions.

The Importance of Sorting Efficiency in the Food Industry

In the food industry, sorting efficiency is directly linked to both the quality and profitability of the products. For instance, nut sorting operations require precision to ensure that only the highest quality nuts are packaged and sent to market. Similarly, shrimp sorting must be conducted to guarantee that only the freshest shrimp are processed for sale. Weight graders significantly enhance sorting efficiency by increasing the speed, accuracy, and consistency of these tasks. This ensures that products not only meet high-quality standards but also fulfill production quotas.

Comparing Auto Weight Sorting Machines vs. Manual Sorting

Manual sorting is time-consuming and inconsistent. Here’s why auto sorting machines outperform traditional methods:

| Feature | Feature | Auto Sorting Machine |

|---|---|---|

| Speed | High-speed conveyor line sorting system | Slow and labor-intensive |

| Accuracy | Precise machine sorting | Prone to human error |

| Cost Efficiency | Lower long-term operational costs | High labor expenses |

| Scalability | High labor expenses | Limited by workforce availability |

Industries adopting weight graders see a 30-50% increase in productivity, making them indispensable in modern food processing.

Key Features of Advanced Sorting Systems

Modern weight sorting equipment has evolved far beyond simple sorting tasks, incorporating advanced technology that enhances both efficiency and product quality. These innovations are crucial for meeting the increasingly demanding needs of industries such as food processing, where consistency, speed, and accuracy are paramount. Below are some of the key features of advanced sorting systems, which significantly improve operational performance:

Multi-Layer Conveyor Line Sorting System

A multi-layer conveyor line sorting system is essential for modern sorting facilities, as it efficiently handles large product volumes in a compact design. It features multiple conveyor belts that operate simultaneously, enhancing processing speed and reducing downtime.

- Minimized Downtime: Continuous product movement leads to increased throughput and productivity.

- High-Capacity Sorting: Ideal for sorting various products, from nuts sorting to fruit sorting and even potato sorting.

- Adaptability: Customizable for various production lines, enabling seamless integration with other technologies, such as machine sorting and vision inspection systems.

AI is revolutionizing sorting with auto sorting machines that utilize machine learning algorithms to enhance sorting accuracy and efficiency over time.

- Improved Accuracy: These systems learn from data to recognize product differences. Whether it’s fruit sorting, nuts sorting, or cold shrimp sorting.

- Dynamic Adjustment: AI can adapt to changes in product types, sizes, and external conditions, ensuring reliable performance across a diverse range of products.

- Cost Efficiency: By automating sorting, these machines reduce labor costs and material waste, making them a valuable long-term investment for sorting facilities.

Conclusion

By understanding the importance of weight graders in sorting systems, businesses can leverage these technologies to enhance processing efficiency, ensure quality control, and minimize waste in food processing operations. From fruit sorting machines to potato sorting machines, weight graders are indispensable tools that drive operational success.

FAQs

What is sorting in food processing?

Sorting in food processing refers to classifying food products based on various parameters, such as size, color, shape, or weight. This process ensures that the products meet consistency, quality, and safety standards before they are packaged or shipped.

What is a weight grader?

A weight grader is a type of sorting equipment that categorizes products based on their weight. It automates the sorting process, ensuring accurate packaging and consistent product quality.

What types of food benefit most from weight-based sorting machines?

Fruits, vegetables, nuts, shrimp, poultry, and processed foods benefit significantly from weight-based sorting machines. Common applications include potato sorting machines, cold shrimp sorting, and nut sorting systems.