Introduction

The walnut processing industry has reached a tipping point. In 2026, simply having a “clean” shell isn’t enough to satisfy the global export market or the high-margin retail sector. As a purchasing manager at an overseas processing plant, you know the struggle: a batch looks perfect on the outside, but inside, moisture levels are off, mold is lurking, or the kernel yield is far below the invoice weight.

Traditional color sorters are blind to these internal failures. To stay competitive, your line needs a brain, not just an eye. This is where the AI-driven walnut in-shell sorting machine changes the game, moving beyond surface-level aesthetics to provide true non-destructive walnut internal quality testing.

I. Seeing the Unseen: The Hardware of 2026 Precision

To achieve top-tier results, you need hardware that captures data humans can’t see. A high-speed CCD industrial camera walnut grader is the foundation, but the secret sauce in 2026 is the integration of hyperspectral sensors.

The Multi-Camera Advantage

WEIGHSORTING systems utilize multiple high-speed CCD industrial cameras equipped with high-definition lenses. This creates a 360-degree digital twin of every walnut in milliseconds. While a standard sorter might miss a hairline crack on the “dark side” of the nut, our grader ensures no defect goes unnoticed.

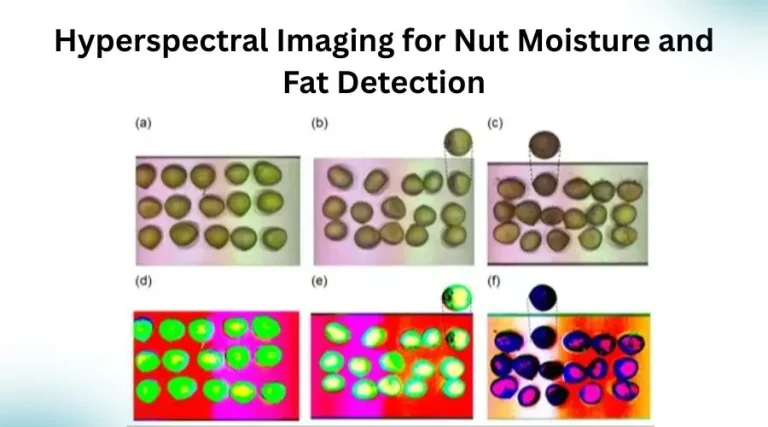

Hyperspectral Imaging for Nut Moisture and Fat Detection

The biggest question we get from managers is: “Does the moisture and fat detection require a separate NIR sensor, or is it integrated into the visual AI path?” At WEIGHTSORTING, we’ve integrated hyperspectral imaging for nut moisture and fat detection directly into the primary inspection tunnel. By analyzing the light-absorption patterns across hundreds of narrow bands, the system “sees” the chemical composition of the kernel through the shell. This allows for real-time rejection of oily or high-moisture nuts that would otherwise lead to rancidity and shelf-life issues.

II. The "Foodman" AI: The Brain Behind the FIAP Technology

If the cameras are the eyes, the deep learning algorithm nut defect detection system is the brain. Specifically, our proprietary FIAP (Food-Intelligence-Analysis-Platform) technology, powered by the Foodman AI, is what separates a modern grader from a legacy machine.

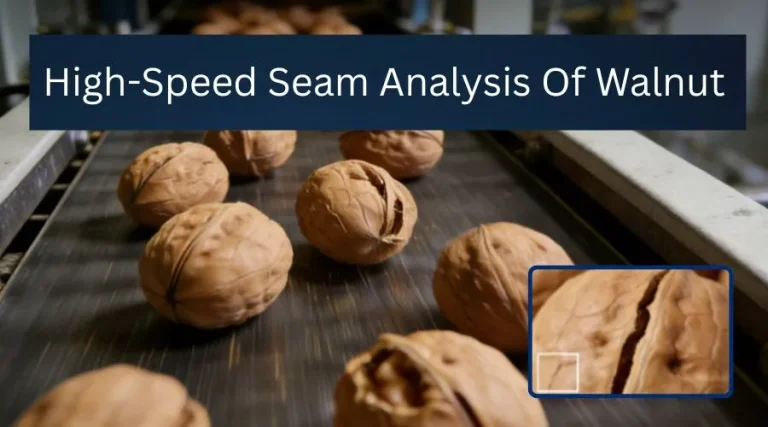

The "Tight Seam" Challenge

One of the most difficult tasks in walnut processing is high-speed seam analysis. You asked: “How does your AI distinguish between a ‘tight seam’ and a ‘slightly cracked’ shell at high speeds?” Standard machines often use simple contrast detection, which leads to high error rates. The Foodman AI uses a deep learning algorithm nut defect detection system trained on millions of walnut images. It recognizes the specific geometric texture of a healthy seam versus the jagged, irregular shadow of a crack. Even at line speeds of several tons per hour, the AI classifies these with surgical precision.

Can the AI be "Re-trained" for Different Varieties?

Whether you are processing California Chandlers, Chilean Serrs, or Chinese Xin2 varieties, the AI is not static. Our AI-driven walnut in-shell sorting machine features a “User-Learning” mode. Your local team can upload images of a new harvest, and the Foodman AI recalibrates its thresholds for color, size, and shell thickness in hours, not weeks. This adaptability is key for non-destructive walnut internal quality testing across diverse global regions.

III. Performance Metrics: Precision at Industrial Scale

Accuracy is a word many manufacturers throw around, but in 2026, the data must be verifiable. A high-capacity walnut sorter ±2g weighing accuracy is the new gold standard for high-end exports.

The Speed-Accuracy Trade-off

You asked a critical question: “You claim ±2g accuracy; is this maintained at maximum throughput?” Most machines lose accuracy as the vibration of the conveyor increases. WEIGHTSORTING uses a stabilized sensor array that compensates for mechanical noise. Our high-capacity walnut sorter ±2g weighing accuracy is rated at 98.5% reliability even when the line is running at its 10-ton-per-hour limit. If the speed exceeds the sensor’s “stable zone,” the system automatically alerts the operator via the HMI.

The Cost of False Rejects (FRR)

Every “good” walnut thrown away is a direct hit to your bottom line. “What is the False Reject Rate (FRR)?” In our latest benchmarks, the Walnut insect damage and mold AI sorter maintains an FRR of less than 0.3%. This means that for every 1,000 nuts rejected, only 3 were actually healthy. By reducing the “good product” waste, the machine often pays for itself within the first 14 months of operation.

Empty Shell and Shriveled Kernel Detection

An AI-driven walnut in-shell sorting machine that only looks at the outside is half-blind. We’ve developed the walnut empty shell and shriveled kernel detection module to use density-mapping. By combining the visual volume of the nut with its precise weight, the AI identifies “light” nuts where the kernel hasn’t fully matured or has shriveled due to heat stress.

The Internal Quality Checklist

Using our non-destructive walnut internal quality testing, the system monitors:

Kernel Yield: Real-time percentage of meat-to-shell.

Black Spot Rate: Identifying internal fungal growth.

Oiliness: Detecting kernels that have begun to break down.

Insect Damage: Finding entry holes too small for the human eye.

This Walnut insect damage and mold AI sorter ensures that your “Premium Grade” bags actually contain premium product.

V. Industry 4.0: Global Support and Remote Diagnostics

Purchasing a machine for an overseas plant is a risk if the support isn’t there. That’s why Industry 4.0 nut processing equipment with remote diagnostics is the only logical choice for international operations.

Remote Assistance: What Does it Actually Cover?

“Can your engineers push software updates or recalibrate sensors from overseas?” Yes. Through our Industry 4.0 nut processing equipment with remote diagnostics portal, our HQ engineers can:

Perform a “Health Check” on all CCD cameras.

Update the Foodman AI with the latest “Insect Damage” recognition patterns.

Troubleshoot electrical faults without a site visit.

The Spare Parts Dilemma

“In the event of a CCD camera failure, do you have a local spare parts hub?” WEIGHTSORTING understands that downtime is the enemy. We maintain professional agents in major walnut-producing regions (USA, Chile, Turkey, and Europe). If a high-speed CCD industrial camera walnut grader component fails, we aim for “Next Flight Out” or local courier delivery to ensure your line is back up within 24–48 hours.

VI. Conclusion: The ROI of Intelligent Sorting

Choosing an AI-driven walnut in-shell sorting machine is an investment in your brand’s future. By integrating hyperspectral imaging for nut moisture and fat detection and an automated walnut kernel yield measurement system, you aren’t just sorting walnuts—you are managing your profit margin with scientific precision.

With a high-capacity walnut sorter ±2g weighing accuracy and a deep learning algorithm nut defect detection system, the “Foodman” technology from Easyweigh provides the most comprehensive non-destructive walnut internal quality testing on the market today.

Ready to see the difference for yourself?

Contact us today to arrange a virtual demo. We can run a sample of your specific walnut variety through our Walnut insect damage and mold AI sorter and provide you with a full yield-accuracy report.

Don’t just sort. Analyze. Optimize. Succeed.

FAQs

How does an AI-driven walnut in-shell sorting machine differ from a standard color sorter?

Traditional color sorters only inspect the surface for stains or discolorations. An AI-driven walnut in-shell sorting machine uses a deep learning algorithm nut defect detection system to analyze the biological structure of the nut. It can identify “invisible” issues like tight vs. open seams, internal maturity, and even chemical bleaching treatments, providing a comprehensive non-destructive walnut internal quality testing solution that surface-level cameras miss.

How does the machine handle walnut empty shell and shriveled kernel detection?

The system combines data from its high-speed CCD industrial camera walnut grader and weight sensors. If a walnut has a standard volume but falls below the weight threshold, the walnut empty shell and shriveled kernel detection logic triggers a rejector. The deep learning algorithm nut defect detection system ensures that even “shriveled” kernels that still have some weight are identified and sorted into the appropriate grade.

Is this equipment suitable for a "washdown" or high-moisture environment?

While walnut processing is typically dry, our Industry 4.0 nut processing equipment with remote diagnostics is built with industrial-grade protection. The high-speed CCD industrial camera walnut grader components are housed in dust-proof, sealed enclosures. For plants requiring strict hygiene, we offer versions that meet HACCP and BRC compliance standards.