Introduction

Artificial intelligence is changing how we detect and sort fruit. The optical sorting machine now plays a key role in this transformation. These optical sorter use smart vision systems to find even the smallest defects in fruit. They spot surface blemishes, bruises, or irregular shapes that could affect quality. When powered by AI, they sort faster, more accurately, and with fewer mistakes.

What Is an Optical Sorting Machine?

An optical sorting machine is a smart tool. It uses high-speed cameras, lighting, and sensors. These tools scan every fruit that moves along a conveyor belt. The fruit and vegetables sorting machine checks each fruit’s size, color, shape, and texture. If the fruit doesn’t meet the standard, it gets removed.

Take an apple sorter, for example. It can tell the difference between a fresh apple and one with spots or bruises. It removes the bad one right away. That keeps only good apples for sale. The result? Better quality and fewer customer complaints.

This kind of sorting used to take many workers. Now, one machine can do the job of dozens. It works day and night, without breaks. And it almost never makes mistakes.

How AI Improves Sorting Machines

AI brings learning and smart decision-making to these machines. A regular system follows set rules. But AI can learn from data. It improves over time. It can even spot problems that are hard for people to see.

For instance, an AI system sorting lemons may find signs of mold that are invisible to the human eye. It removes those lemons before they reach the store. This keeps customers safe.

AI sorting systems also adjust to changes. If the lighting changes or if the fruit looks different in a new season, the system still works well. There’s no need to stop and reset it. That saves time and avoids waste.

The optical sorter also tracks trends. If a certain defect starts showing up more often, the machine alerts the operator. This could point to a problem in how the fruit was picked or stored.

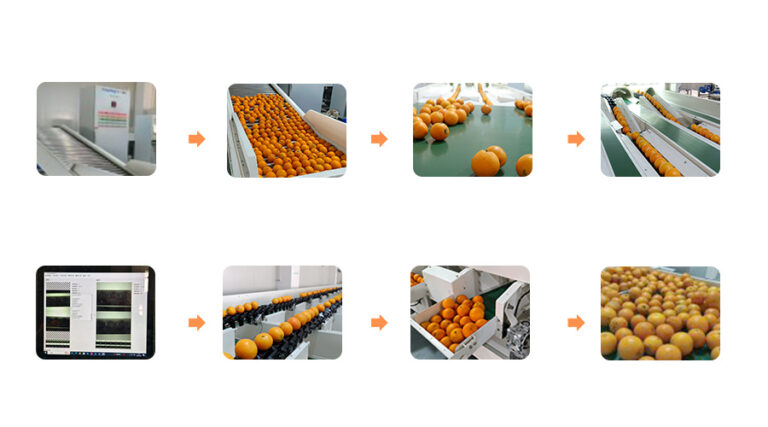

How Does It Work?

Fruit goes onto a conveyor belt. Cameras and sensors scan it fast—hundreds of times per second. The fruit sorter system builds a full picture of the fruit.

AI compares this picture with a database. Good fruit moves forward. Bad fruit is pushed aside with air or a small arm.

Think about cherries. A cherry sorter can check up to 500 cherries every second. It finds overripe or cracked ones and removes them right away. No person can work that fast or that accurately.

Some advanced vision sorting machines can even look inside fruit. They use near-infrared or X-ray tools. These find hidden problems like internal rot or insects.

Benefits of AI in Fruit Sorting

More Accurate Sorting

AI cuts down on mistakes. The fruit sorter knows the difference between natural color changes and real damage. That means fewer good fruits are thrown out, and more are sold.

For example, it can tell the difference between a tomato that is naturally green and one that is turning bad.

Lower Labor Costs

A job that once needed many workers now needs fewer people. This lowers labor costs. The vision sorting machine also makes the workplace safer by reducing repetitive tasks.

Better Information and Faster Fixes

These fruit sorters show live data. You can see trends and fix problems early. One blueberry farm found that soft berries were being rejected too often. The cause was bad handling during picking. Once fixed, they saved a lot of fruit.

Less Waste, More Sustainability

Because the vision sorting machine only removes bad fruit, less is thrown away. That’s better for the planet and saves money.

Happier Customers

Good fruit means happy buyers. When people find only fresh, clean fruit in the store, they come back. That builds brand trust and loyalty.

These Optical Sorter Machines Used and future

The Use of Sorter Machines

These machines are used for many fruits: apples, oranges, cherries, blueberries, mangoes, and grapes. Each fruit has different needs.

For apples, the machine checks for firmness and skin spots. For grapes, it looks for color and mold. In mangoes, it finds skin damage or sap burns.

Each machine can be trained with special data. For example, in grape sorting, the system learns to spot dry grapes or leftover stems.

The Future of Optical Sorter

The future looks bright. Soon, vision sorting equipments may use new cameras to see even more. They might check sugar content or how ripe the fruit is on the inside.

AI might also predict problems. If it rains too much before harvest, the machine could expect more defects. It can adjust before the fruit arrives.

Robots may also help pack fruit after sorting. They’ll put fruit into boxes based on size or quality. This full system—from sort to pack—could work without people.

Smaller farms might also benefit. New machines are getting smaller and cheaper. This means everyone—not just big companies—can use AI for better fruit sorting.

Conclusion

AI is changing how we check fruit quality. With optical sorting machines, producers now sort better and faster. They save time, cut costs, and reduce waste.

These machines aren’t just tools. They’re smart partners that help deliver great fruit to stores and customers.

If you grow or sell fruit, now is the time to invest. AI-driven sorting is no longer the future. It’s the new standard.

FAQs

What is an AI-powered optical sorter?

An AI-powered optical sorting machine uses artificial intelligence and advanced vision systems to inspect and categorize fruit. It analyzes quality traits like size, shape, color, and visible or hidden defects. But what makes it truly different? Unlike older systems, it doesn’t just follow fixed rules. The AI sorting system can learn deeply. With each pass of fruit, the machine improves its identification skill. Over time, this learning process leads to greater accuracy, more effective sorting, and fewer errors.

How does AI improve fruit sorting efficiency?

AI sorting technology brings more than just speed. By utilizing deep learning algorithms, the fruit sorter can detect small bruises or early signs of rot. The sorting system adapts instantly to changes, whether it’s a shift in lighting or a batch of unusually colored fruit. As a result, the sorting process becomes faster, more precise, and far more reliable, even in unpredictable conditions.

What types of fruits can be sorted?

From soft berries to firm apples, these AI optical machines handle it all. Is one machine good enough for all these fruits? Yes, with proper training. AI allows the sorter to learn the distinct characteristics of each fruit. For example, it can identify skin discoloration in tomatoes. Each sorting session can be tailored to meet the specific quality standards of the corresponding fruit.