Introduction

In today’s competitive processing industries, precision and speed are critical. Whether you handle fruits, vegetables, nuts, candies, or other commodities, an efficient vision sorting machine helps ensure consistent quality. As demand for automation grows, advanced optical sorting machines and automated vision inspection systems have become essential tools in modern production lines.

These smart systems use high-resolution vision system cameras to identify and sort products based on size, shape, color, and surface defects. From a tomato separator machine to an apple sorting machine or a nut sorting machine, the right features can significantly improve productivity, reduce waste, and ensure top-grade output.

This guide explains the top 10 functional features to look for in a vision inspection system to help you choose the best solution for your needs. If you’re looking for a reliable, high-performance solution, the Easyweigh Fruit Optical Sorting Machine offers all of these advanced features in one robust system.

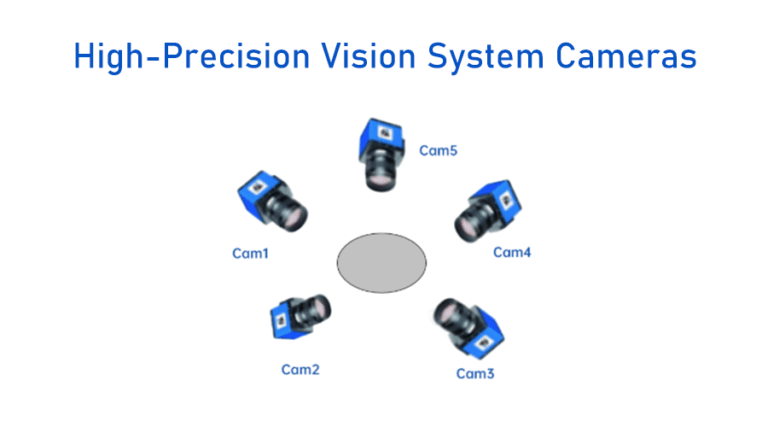

1. High-Precision Vision System Cameras

A powerful vision sorting machine starts with a reliable vision system camera. These cameras capture detailed images at high speed, ensuring every product is scanned clearly. High-resolution imaging enables accurate defect detection, even at fast conveyor speeds.

Whether you’re using a fruit sorter, candy sorting machine, or potato sorting machine, sharp image capture reduces false rejects and improves accuracy. The Easyweigh Fruit Optical Sorting Machine is equipped with ultra-clear industrial cameras that deliver outstanding detection of color variation, bruises, mold, and deformities.

2. Smart AI Sorting Algorithms

Today’s machine vision inspection technology relies on AI to identify patterns. These vision inspection systems analyze shape, size, texture, and color in real time. AI algorithms help separate acceptable products from defective ones quickly and automatically.

Over time, AI-powered smart sorting systems learn from new data, improving detection accuracy and helping reduce waste. Easyweigh’s intelligent algorithm adapts to each fruit variety and size, minimizing calibration time and maximizing accuracy.

3. Multi-Parameter Sorting Capability

A versatile optical sorting machine must evaluate multiple product attributes. These include size, weight, color, shape, and surface quality. Multi-parameter sorting ensures products meet quality standards for different grades or markets.

This capability is critical in sorting facilities or sorting companies that handle mixed produce or large volumes. The Easyweigh Fruit Optical Sorting Machine offers up to 6 sorting levels, allowing full customization based on customer requirements.

4. High-Speed Automation

Fast and efficient auto sorting machines are essential for modern factories. High-speed conveyors, combined with real-time image processing, enable accurate sorting at thousands of units per minute.

From a high-volume auto avocado machine to a bulk apple sorting machine, automated speed increases output and reduces labor costs. Easyweigh’s system handles large-scale production with ease, ensuring high throughput without compromising accuracy.

5. Intelligent Ejection Systems

Accurate sorting depends on precise rejection. Camera vision inspection systems use air jets or push arms to remove defective items from the product flow. These ejection systems must be fast and accurate to avoid removing good products.

This feature enhances the performance of any automatic sorting machine and helps protect overall yield. The Foodman Fruit Optical Sorting Machine uses high-speed air jet ejection, precisely timed to match product speed and position.

6. Real-Time Monitoring and Data Analytics

A modern vision system for quality inspection should provide real-time performance insights. Continuous data tracking shows defect rates, trends, and system performance.

These analytics help optimize sorting accuracy and support compliance with food safety and quality standards. They’re particularly valuable in large sorting facilities. Easyweigh’s built-in dashboard delivers instant data visualizations, batch records, and downloadable reports.

7. Modular and Scalable Design

A future-ready sorting machine must adapt as your business grows. Look for modular designs that support the addition of more lanes, cameras, or ejection systems.

Scalability is important for seasonal industries like fresh fruit or vegetable processing. Whether you’re upgrading a tomato separator machine or expanding your potato sorting machine, flexible architecture matters. Foodman’s scalable platform supports line expansions, multi-fruit adaptations, and remote upgrades.

8. Easy-to-Use Interface with Recipe Control

Efficient operations require simple controls. Touchscreen interfaces with multi-language support allow fast setup. Automated vision inspection systems with recipe management make product changeovers quick and consistent.

This is essential for companies running mixed lines—switching between apples, avocados, nuts, or candies with a single machine sorting platform. Easyweigh’s intuitive interface allows operators to switch recipes with a single tap, reducing downtime.

9. Hygienic and Durable Construction

In food processing, hygiene is critical. Your vision inspection system should be easy to clean, with stainless steel frames and IP-rated protection.

This ensures safe operation in environments where dust, moisture, or sticky residues are common, such as candy or fresh produce lines. Easyweigh’s fruit sorter is made from food-grade materials, with smooth surfaces that are easy to sanitize.

10. Integration with Existing Systems

A top-performing vision sorting machine should integrate seamlessly with upstream and downstream equipment. That includes conveyors, packing lines, and ERP or MES software systems.

Smooth integration boosts line efficiency and ensures that sorting data can support traceability and quality management systems. Easyweigh’s integration-ready design works with most third-party production equipment and control systems.

Conclusion

Understanding what is sorting is key to investing in the right solution. Today’s vision systems for inspection do more than sort—they monitor, analyze, and optimize performance.

From optical sorting machines to specialized tools like the autocado avocado machine, nut sorting machine, or candy sorting machine, every feature plays a role in boosting quality and efficiency.

Choose a vision sorting machine that delivers high-resolution imaging, AI-driven sorting, real-time analytics, and robust construction. The Foodman Fruit Optical Sorting Machine brings all these features together—helping you ensure quality, increase yield, and stay ahead in a competitive market.

Whether you run a sorting company, operate a large sorting facility, or manage a single automatic sorting machine, Foodman provides the reliable solution you need for smart, high-speed sorting.

Add Your Heading Text Here

What industries use vision sorting machines?

You’ll find them in many sectors: fruit and vegetable processing, snack production, nuts and grains, meat and seafood, and even candy manufacturing. Wherever product quality matters, a vision sorting machine plays a key role.

What makes multi-parameter sorting important?

Multi-parameter sorting looks at more than one factor at a time—like size, color, weight, and defects. This leads to more precise classification. Imagine sorting apples that are red, round, and perfectly sized—all at once. It saves time and improves quality control.

Why is AI important in vision sorting machines?

AI plays a big role in sorting today. It allows the sorter machine to “learn” and improve accuracy over time. For example, it can recognize subtle differences between ripe and overripe fruit, or between a good nut and a moldy one. With AI, sorting machine becomes smarter and more adaptive.