Introduction

A production line where thousands of snack packs, bottles, or packaged products fly past every minute. How can we ensure products meet standards on fast-moving production lines?

That’s where a vision inspection system steps in. Think of it as the “eyes” and “brain” of automated quality control. It sees what humans can’t, reacts faster than any person could, and keeps production running smoothly.

But what is a vision inspection system, really? How does it work? And why is it becoming indispensable across industries—from food and beverage to packaged products and pharmaceuticals?

Let’s explore this incredible technology that’s quietly transforming food processing lines behind the scenes.

What Is a Vision Inspection System?

A vision inspection system is a combination of sensitive industrial cameras, TDI sensors, Foodman AI inspection algorithm and HMI displays real-time detection, that work together to automatically inspect products for quality, accuracy, or defects.

In simple terms, it’s a machine that “looks” at your product and decides whether it’s good or not.

These systems are often part of machine vision systems—a branch of artificial intelligence that allows machines to interpret visual information just like humans do. However, unlike the human eye, a machine vision inspection system never gets tired, never blinks, and never misses a flaw.

Whether it’s checking the seal on a food package, verifying a label, or inspecting Packaged misalignments, vision systems for inspection ensure every product meets exact standards.

How Does a Vision Inspection System Work?

Here’s a simplified way to imagine it.

Think of a camera vision inspection system as a supercharged camera paired with a powerful brain. When a product passes in front of the camera:

The vision inspection equipment captures an image.

The vision inspection software analyzes the image in milliseconds.

The software compares it to preset standards or models.

The vision system for inspection makes a decision — accept, reject, or alert an operator.

This entire process happens almost instantly, without slowing down the production line.

A single vision inspection machine can perform hundreds of checks every second, spotting problems like:

Missing labels

Incorrect fill levels

Damaged packaging

Misaligned parts

Surface defects

It’s like having an army of quality inspectors who never rest.

In today’s hyper-competitive world, companies can’t afford inconsistency. Consumers expect flawless products every time. Retailers demand compliance. And even a single recall can damage a brand’s reputation permanently.

That’s why vision systems for inspection have become the backbone of quality assurance.

Here’s why manufacturers love them:

Accuracy – A machine vision inspection system detects even microscopic defects (scratches, dents, gaps, etc) of packaged products invisible to the human eye.

Speed – Automated inspection keeps up with high-speed production lines.

Consistency – inspection machines meet international safety standard

Traceability – Every inspected product can be logged and recorded for full accountability.

In short, a vision inspection system guarantees that what leaves your factory is exactly what you intended.

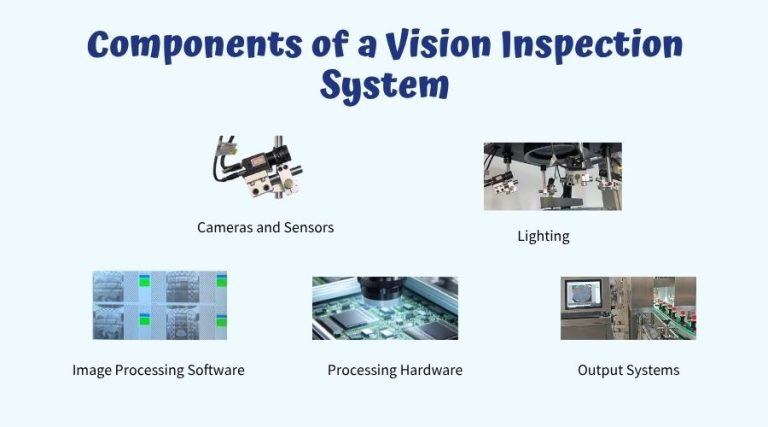

Components of a Vision Inspection System

To understand the magic behind the technology, let’s break it down into its key parts:

1. Cameras and Sensors

These are the eyes of the system. A FDM camera’s vision inspection system uses one or multiple sensitive industrial cameras—sometimes high-speed or 3D—to capture detailed images.

2. Lighting

Proper lighting ensures that surfaces, colors, and textures are clearly visible. LED lighting is commonly used to highlight specific features.

3. Image Processing Software

This is the brain. The Foodman AI algorithm vision inspection software analyzes captured images, looking for deviations from the “ideal” model. It can measure dimensions, detect color changes, and recognize barcodes or text.

If cameras are the eyes, vision inspection software is the brain.

It’s responsible for processing images, interpreting data, and making real-time decisions. Modern software uses AI and deep learning to improve accuracy over time—just like how humans learn from experience.

For example, if a vision inspection system is trained to recognize cracks on glass bottles, it becomes better at distinguishing real defects from harmless marks with every scan.

This adaptability makes today’s vision inspection solutions far more powerful than traditional manual checks.

4. Processing Hardware

The high-speed processors crunch the data instantly, even in demanding environments.

5. Output Systems

Finally, the vision inspection solution sends commands to HMI displays—rejecting defective items, alerting operators, or storing data for reports.

Each component plays a vital role in ensuring precision, speed, and accuracy.

The beauty of machine vision systems is their versatility. No matter the product or industry, they can be adapted to meet specific needs.

Food

In food production, vision systems for quality inspection verify that packaging is sealed, labels are correct, and products are free from foreign objects. For example, a vision labeler ensures every snack bag has the right label placed perfectly straight.

Cosmetics & Personal Care Industry

Machine vision inspection systems detect flaws in lotion, cream, and shampoo containers, as well as deformations and scratches. The inspection machine with seal verification can inspect seals on pouches and tubes. Ensures labels are straight and blemish-free.

Beverage Industry

A vision inspection machine identifies micro-cracks, gaps, and dents in aluminum

cans. Ensure that the correct placement and readability of QR codes and batch info. Detects scratches or damage on the can exteriors.

Pharmaceuticals

Medicine packaging and pill inspection are critical. Automated vision inspection systems ensure every capsule is intact and every label is readable, safeguarding consumer health.

Packaging products

In packaging lines, vision systems confirm the presence of barcodes, batch numbers, and expiry dates. A missing code could mean product recalls—something no brand wants.

In short, anywhere quality matters, vision inspection systems play a vital role.

Why Businesses Are Investing in Automated Vision Inspection Systems

You might wonder—why are more factories switching to automated vision inspection systems now than ever before?

Here are a few reasons:

Labor shortages – Automated systems reduce reliance on manual inspectors.

Higher production speeds – Human eyes can’t keep up with modern lines producing thousands of units per minute.

Cost savings – While the initial investment in vision inspection equipment might seem high, the return on accuracy, reduced waste, and better efficiency is enormous.

Data-driven decisions – Systems record every inspection, helping companies analyze trends and improve quality control processes.

A simple example: Imagine a snack manufacturer installing a vision inspection machine to check chip packaging. Within a week, it identifies that one sealing machine is underperforming. That single insight prevents thousands of defective packages from shipping—saving money and brand reputation.

Vision Systems vs. Manual Inspection

Let’s be honest—manual inspection has limits. Even the most dedicated workers can’t maintain perfect focus eight hours a day.

Vision system inspection, on the other hand, never gets distracted. It doesn’t need breaks, and it delivers identical results 24/7.

Moreover, a machine vision system can measure microscopic details invisible to human eyes, providing precision that manual methods can’t match.

That doesn’t mean people are replaced—it means they’re empowered. Operators can focus on analysis, maintenance, and improvement rather than repetitive tasks.

The Future of Vision Inspection

The future is even more exciting. As artificial intelligence, deep learning, and automation continue to advance, machine vision systems are becoming more intuitive and flexible.

Soon, vision inspection systems won’t just detect defects—they’ll predict them. Imagine a vision inspection system that analyzes patterns to alert operators before a machine starts producing faulty products. That’s predictive quality control—and it’s closer than you think.

Why Easyweigh in Vision Inspection Solutions

At Easyweigh, we understand that quality isn’t optional—it’s essential. Our vision inspection systems are designed to provide reliable, real-time quality assurance that integrates seamlessly into your production lines.

Whether you’re in food, beverage, seafood, or packaging, our camera vision inspection systems and automated vision inspection systems help ensure your products meet the highest standards of safety and consistency.

From vision inspection equipment to advanced vision inspection software, we deliver complete, customized solutions that keep your business competitive in a fast-changing world.

Conclusion

To sum it up, a vision inspection system isn’t just a fancy camera—it’s your factory’s most reliable quality control partner.

By combining precision, speed, and intelligence, machine vision inspection systems make sure every product is perfect before it leaves the line.

So, whether you’re checking labels, counting products, or verifying seals, remember this: investing in a vision inspection solution today means fewer errors, safer products, and happier customers tomorrow.

FAQs

What is a vision inspection system?

A vision inspection system is an automated technology that uses sensitive industrial cameras, Foodman AI algorithm and FDM vision inspection software to capture and analyze images of products in real time. It identifies defects, verifies labels, and ensures quality control without human intervention. This system is essential for high-speed industries such as food, beverage, and the pharmaceutical industry.

How does a machine vision inspection system work?

A machine vision inspection system captures images of products using advanced cameras and then processes them through vision inspection software. The software compares the images against predefined standards. If an error—like a missing label, incorrect shape, or surface defect—is detected, the system automatically rejects or flags the product for review.

What are the benefits of using vision systems for inspection?

Vision systems for inspection deliver precision, consistency, and speed. They eliminate human error, reduce production waste, and ensure products meet strict quality standards. In addition, these automated vision inspection systems provide real-time data insights that help manufacturers improve efficiency and reduce costs.