Introduction

Vision sorting machines play an indispensable role during peak harvest seasons. In fruit processing plants, apples roll off the conveyor belt like thousands of red marbles every minute. In the past, workers relied on their eyes and intuition to inspect fruit for bruises, color variations, or deformities. However, as product demand surged, human vision alone could no longer meet the rapidly increasing production requirements. The high-speed sorting capabilities of vision sorting machines have significantly accelerated fruit grading efficiency.

This intelligent piece of technology doesn’t get tired, distracted, or inconsistent. It “sees” using advanced cameras and software, detecting imperfections faster and more accurately than any human could.

In today’s global food industry, where quality and safety standards are higher than ever, AI vision sorting machines and optical sorting systems are no longer luxuries — they’re necessities. Whether it’s apple grading, grape optical sorting machines, or general fruit sorter lines, these systems have changed how we define perfection.

Let’s explore how these powerful technologies work, why they matter, and how they’re shaping the future of automated food processing.

What Exactly Is a Vision Sorting Machine?

At its simplest, a vision sorting machine is an automated inspection and sorting device that uses cameras, TDI sensors, and artificial intelligence to evaluate and separate products based on their physical characteristics — color, size, shape, or defects.

You can think of it as a highly trained pair of robotic eyes and a brain that makes instant decisions.

Unlike traditional sorting machines, which rely on mechanical separation or weight-based sorting, machine vision systems add intelligence to the process. They “see” each object on the production line using cameras and analyze it in milliseconds through sophisticated vision inspection software.

The system then decides: keep it or reject it.

Whether it’s checking the ripeness of an apple in an apple sorting machine or spotting a shriveled grape in optical sorting machines for fruit, the vision system for sorting ensures only the best products make it to packaging.

While the technology may sound complex, the process is remarkably intuitive when broken down.

Here’s how a machine vision sorting machine works step-by-step:

Imaging and Lighting:

Products pass through the inspection zone where high-speed cameras capture multiple images. Lighting plays a critical role — different wavelengths (visible, infrared, ultraviolet) help reveal details invisible to the human eye.

Image Analysis:

The vision system processes each image, identifying characteristics like color tone, size, or foreign objects.

Decision-Making:

Using AI deep learning function to train models, the vision system inspection software determines whether the product meets quality standards.

Sorting:

Air jets or mechanical arms remove defective items instantly, ensuring only top-quality products move forward.

This all happens in real time — thousands of products per minute — with precision accuracy.

That’s the magic of sorting with machine vision: fast, flawless, and fully automated.

The Key Components of a Vision Sorting Machine

To understand what makes a vision sorting machine so advanced, let’s look under the hood:

1. Camera Vision Inspection System

The “eyes” of the machine. These high-resolution industrial cameras capture detailed images of each item, often from multiple angles. Some systems even use 3D imaging for a more complete analysis.

2. Lighting Module

Good lighting is essential. LEDs, lasers, or strobes ensure that every detail — color shade, bruise, or speck — is visible for accurate inspection.

3. Vision Inspection Software

Based on Foodman’ s AI self-developed algorithm, Using machine vision systems, the software compares real-time data with preset standards to make decisions on the fly.

One of the most powerful aspects of a vision sorting machine lies in its vision inspection software.

This software is where the decision-making happens. It uses algorithms, pattern recognition, and sometimes artificial intelligence to identify what’s “good” and what’s not.

Modern machine vision systems can even be trained to recognize new types of defects — adapting over time without reprogramming. This flexibility makes them ideal for industries where products vary by season or region.

4. Ejection Mechanism

Once a flaw is detected, precise air jets or diverter gates remove defective products instantly.

Together, these components make optical sorting systems indispensable in modern production lines.

5. Designing a Vision Sorting Machine

Creating a design vision sorting machine involves both engineering precision and creative problem-solving.

Engineers must consider:

Lighting angles for optimal image capture.

Camera placement to ensure full 360° product visibility.

Software calibration for defect sensitivity.

Mechanical design for smooth product flow.

The best optical sorter machines are customized to the specific needs of each production line — whether it’s fragile grapes, dense nuts, or delicate berries.

Machine Vision Systems Across the Food Industry

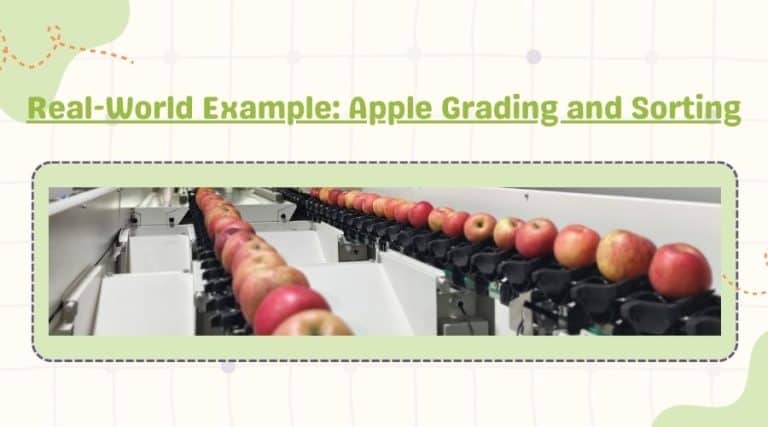

Real-World Example: Apple Grading and Sorting

Let’s take a real-world example — apple grading.

Apples may all look similar at first glance, but each one has its own unique shape, color gradient, and imperfections. Using a vision sorting machine, producers can grade apples by color intensity, size, and surface blemishes within seconds.

The apple sorting machine captures high-resolution images of every apple as it moves down the conveyor belt. The vision system for sorting then analyzes these images and classifies each apple according to pre-defined quality parameters.

Perfect apples go to premium packaging. Slightly blemished ones may be redirected for juice production. Defective ones? Rejected.

This process doesn’t just ensure consistency — it maximizes profitability.

Other Solutions

Machine vision sorting isn’t limited to apples. These systems are used across a wide range of food processing sectors:

Grapes: Grape optical sorting machines detect discoloration or mold, ensuring only perfect grapes are packed.

Nuts: Detecting shell fragments or off-color nuts in mixed batches.

Vegetables: Sorting carrots, tomatoes, or peppers by size and ripeness.

In each case, machine vision based object sorting ensures product uniformity, reduces waste, and enhances brand reliability.

Why Vision Sorting Machines Matter

So, why are these systems becoming essential in modern production?

1. Unmatched Accuracy

A machine vision sorting machine detects flaws invisible to the naked eye — like subtle discoloration or foreign materials.

While humans can inspect hundreds of items per hour, optical sorting systems can process tens of thousands.

3. Consistency

Humans get tired; machines don’t. Every apple, grape, or nut gets evaluated with the same accuracy from start to finish.

4. Food Safety and Compliance

By removing contaminated or defective items automatically, vision systems color sorting machines help maintain high food safety standards and meet regulatory requirements.

5. Data Collection and Traceability

Every item inspected generates valuable data — trends, defect rates, and performance analytics — which can be used to optimize future production.

The Economic Impact of Vision Sorting

The optical sorting machines for fruit and food industries are growing rapidly. Reports suggest that the global automated vision sorting market is expanding at over 8% CAGR.

Companies adopting vision sorting machines experience:

Lower labor costs

Higher production yield

Greater customer satisfaction

Reduced product recalls

In short, this technology doesn’t just improve quality — it boosts profitability.

Conclusion

In the modern food industry, seeing clearly means succeeding confidently.

A vision sorting machine doesn’t just sort food — it safeguards brand reputation, enhances consumer trust, and streamlines operations. From apple grading to grape optical sorting machines, these technologies have become the cornerstone of efficient, intelligent, and sustainable production.

As machine vision systems continue to evolve with AI and data integration, the future of sorting with machine vision looks brighter than ever.

For producers who value precision and consistency, investing in a vision sorting machine isn’t just a technological upgrade — it’s a competitive advantage.

FAQs

What industries use vision sorting machines?

Although most popular in the food sector, vision sorting machines are also used in other industries. Examples include:

Apple grading and apple sorting machines in fruit processing.

Grape optical sorting machines in wine production.

Machine vision based object sorting in pharmaceuticals and electronics to detect product defects.

These systems are adaptable across industries that require precision and quality control.

What are the main benefits of sorting with machine vision?

Sorting with machine vision offers numerous benefits, including:

Faster inspection speeds

Consistent quality control

Reduced human error

Better food safety compliance

Lower production waste

These advantages make machine vision sorting machines an essential investment for modern manufacturers.

What makes Easyweigh’s vision sorting machines stand out?

Easyweigh’s vision sorting machines are designed with cutting-edge optical sorting systems, intuitive vision inspection software, and adaptive machine vision systems that handle everything from apples to potatoes. Each vision system for sorting is built for precision, flexibility, and reliability — making them a trusted solution for businesses aiming for excellence in food quality and safety.

Subscribe to Our New Blogs

The Definitive Guide to High-Speed Meat Portion Grading and Batching Systems

Introduction In the high-stakes world of meat processing, 2026 has become the year where the “yield gap” separates profitable plants from those struggling to stay afloat. If you are running a steak production line, you know the reality: every gram

The 2026 Guide to Weight Sorting & Fish Bone Detection

Introduction The salmon industry in 2026 is a high-stakes game where the margin for error has practically vanished. If you’re running a processing plant, you know the nightmare: a single bone-in complaint from a Tier-1 retailer can jeopardize a multi-million

The 2026 Agent’s Guide: How to Source Certified Weight Sorting Machines from Asia

Introduction The manufacturing landscape has shifted. If you are an overseas agent looking for a weight sorting machine manufacturer OEM/ODM, the year 2026 marks a massive turning point. Gone are the days when “Made in China” simply meant low cost.

The 2026 Buyer’s Guide to AI-Driven Walnut Sorting & Non-Destructive Internal Quality Testing

Introduction The walnut processing industry has reached a tipping point. In 2026, simply having a “clean” shell isn’t enough to satisfy the global export market or the high-margin retail sector. As a purchasing manager at an overseas processing plant, you

The Ultimate Guide to Automated Seafood Sorter

Introduction Have you ever watched a seafood processing line and wondered how on earth people manage to sort thousands of fish, shrimp, or shellfish by size and weight… without losing their minds? Years ago, the answer was simple: a tired

Hygienic Meat Sorting Equipment for Poultry Processing

Introduction Meat sorting is one of the most crucial steps in ensuring the highest quality products while maintaining stringent food safety standards in the world of poultry processing. Because food safety standards are developing. From chicken sorting machines to automatic