Introduction

The salmon industry in 2026 is a high-stakes game where the margin for error has practically vanished. If you’re running a processing plant, you know the nightmare: a single bone-in complaint from a Tier-1 retailer can jeopardize a multi-million dollar contract. It isn’t just about the fine. It’s about the trust. For years, the industry relied on manual labor and basic sorting machine technology, but the “good enough” era is over. Today, achieving a HACCP compliant salmon processing line requires more than just a belt and a scale; it requires an intelligent vision and weighing system for fish that can think, see, and sort with superhuman precision.

At WEIGHTSORTING, we’ve watched as processors struggle with “gapping” (flesh separation) caused by harsh sorters and missed pin bones that lead to costly recalls. This guide explores how an integrated fish grading and X-ray inspection system—utilizing dual energy X-ray for fish bone detection—is revolutionizing the floor. We aren’t just talking about a weight sorter anymore. We are talking about total quality assurance from the moment a fillet hits the line until it’s sealed for the consumer.

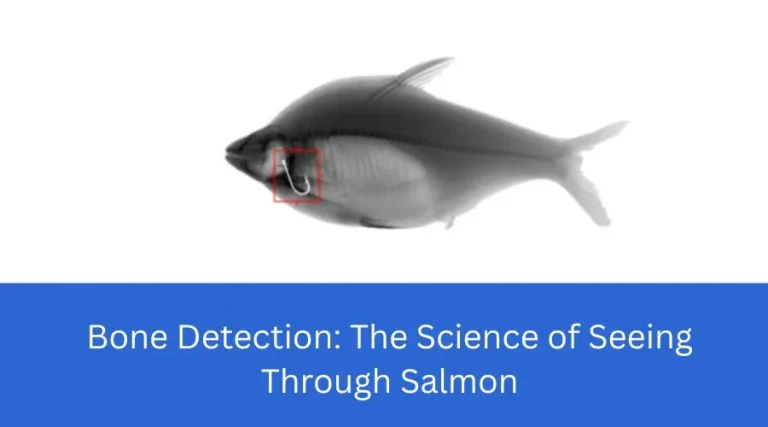

I. Bone Detection: The Science of Seeing Through Salmon

Let’s talk about the invisible enemy: the pin bone. These tiny, calcified needles are the bane of every quality control manager’s existence. Why do legacy systems fail to find them? To answer that, we have to look at the physics of the scan.

DEXA vs. Single-Energy: Why One Scan Isn't Enough

The most frequent question we receive is: “Does your system use Dual-Energy X-ray (DEXA) or Single-Energy?” Standard X-ray machines are essentially high-powered flashlights. They work well for high-density foreign objects like metal or glass because those items stand out against the soft flesh of the fish. However, a salmon pin bone has a density incredibly close to the surrounding muscle and fat. In a single-energy scan, the bone often “blurs” into the meat, becoming invisible to the sensor.

This is where dual energy X-ray for fish bone detection changes the game. By using two distinct energy levels, the system can perform a mathematical “subtraction.” It identifies the organic matter (the flesh) and effectively hides it from the image, leaving only the high-contrast calcified structures behind. This automatic fish bone detector for fillets identifies “low-contrast” contaminants that were previously impossible to catch.

AI vs. Myosepta: Solving the "Fat Line" False Positive

If you’ve operated an X-ray line, you know the “Fat Line” headache. You’ve likely asked: “How does the software distinguish between the ‘fat lines’ (myosepta) of the salmon and actual bones?”

In the past, high-fat Atlantic or King salmon would trigger constant false rejects. The machine would see a thick line of fat and flag it as a bone, leading to massive product waste. Modern Bone Detection now uses an intelligent vision and weighing system for fish powered by deep learning. Instead of just looking at density, the AI analyzes the geometry of the object. A pin bone is rigid, straight, and has a specific calcification signature. A fat line is organic, curved, and follows the muscle structure. Our high-resolution X-ray for calcified fish bones can tell the difference in milliseconds, ensuring you only reject what is actually dangerous.

II. Weight Sorting: Precision Without the Bruising

Once the bone is gone, the fillet must be graded. But here’s the catch: salmon is incredibly delicate. If your weight sorter hits the fillet too hard, you get “gapping”—the muscle fibers pull apart, and the fillet loses its premium market value.

Gentle Discharge: Protecting Market Value

A common pain point for managers is: “What mechanism do you use to divert fillets (Air blast, paddle, or sliding flipper) to prevent ‘gapping’ or bruising?”

Air blasts are efficient for small items but can cause internal bruising in heavy fillets. Paddles are often too aggressive, striking the “leading edge” of the fish and causing tears. The 2026 standard for a salmon grading line with gentle discharge is the sliding flipper.

In a multi-stage weight sorter for fresh fish, these flippers glide the fillet across the belt rather than striking it. This sweeping motion preserves the structural integrity of the flesh. When you use an integrated fish grading and X-ray inspection unit, the sorting is seamless. The weight sorter knows the exact weight and bone status of the fillet before it even reaches the discharge gate, allowing for a perfectly timed, gentle transition.

III. Hygiene & Maintenance: The "Washdown" Standard

In a salmon plant, “clean” isn’t just a suggestion; it’s a regulatory requirement. Between the salt brine and the fish oils, your sorting machine is essentially living in a corrosive bath.

Open Frame Design: Why 304 Stainless Steel is Professional Choice

Managers often ask: “Is the machine designed with ‘Open Frame’ 304 Stainless Steel?” Yes, and for good reason. While some use plastic or lower-grade metals, a 304 stainless steel food grade conveyor is the only material that truly stands up to the long-term corrosive effects of brine and fatty acids. But the material is only half the story. The “Open Frame” design means there are no hollow tubes or hidden crevices. In a washdown IP69K fish processing equipment environment, bacteria like Listeria look for “dead zones” to hide. Our open-frame architecture ensures that every square inch of the machine is reachable by high-pressure sanitation hoses.

The 60-Second Rule: Maintenance Speed

Downtime is the silent killer of profit. You should always ask: “Can the belts be removed for cleaning in under 60 seconds without tools?”

On a modern HACCP compliant salmon processing line, you shouldn’t need a toolbox to sanitize a belt. Easyweigh systems feature quick-release tensioners. Your sanitation crew can strip the 304 stainless steel food grade conveyor, clean it, and have the sorting machine back up and running in a fraction of the time required by legacy systems.

IV. The Product Matrix: Technical Specifications

To be the top weight sorter on the market, the numbers have to back up the talk. Below is the technical breakdown for our integrated fish grading and X-ray inspection modules.

| Specifications | X-Ray Inspection System For Fishbone | Dual Lane Weight Grader |

|---|---|---|

| Accuracy | Fishbone 0.1mm Stainless steel ball 0.2mm Stainless steel wire 0.1mm*2 Ceramic, glass balls 0.8mm | ±1g ~ ±5g |

| Waterproof | IP66 | IP66 |

| Highlight | 0.1mm TDI detector | High-Speed A/D Sampling Module |

V. Conclusion

The transition to an intelligent vision and weighing system for fish isn’t just about catching more bones; it’s about data and trust. When you can prove to your buyers that your HACCP compliant salmon processing line uses high-resolution X-ray for calcified fish bones, you aren’t just a supplier—you’re a premium partner.

By combining a multi-stage weight sorter for fresh fish with integrated fish grading and X-ray inspection, you eliminate the manual errors that lead to recalls. You protect your brand. You protect your margins. And most importantly, you ensure that “Pure Fillets” isn’t just a marketing slogan—it’s a guarantee.

Are you ready to see the DEXA difference? Would you like us to run a custom yield-analysis on your specific fillets? Contact Easyweigh today to schedule a demonstration of our dual energy X-ray for fish bone detection and see how we can optimize your salmon grading line with gentle discharge. Let’s build the future of fish processing together.

Why is Dual-Energy X-ray (DEXA) better than single-energy for fish bone detection?

Standard single-energy X-ray systems often fail to find pin bones because the density of the bone is too similar to the salmon flesh, causing them to “disappear” in the scan. Dual energy X-ray for fish bone detection uses two different energy spectra to scan the product. By comparing the two images, the system can mathematically “subtract” the meat, leaving a high-contrast view of even the finest calcified fish bones. This makes it the superior choice for high-stakes Bone Detection.

How does an automatic fish bone detector for fillets avoid false rejects from fat lines?

Fat lines, or myosepta, have long been a headache for processors because their density can mimic that of a bone. Our automatic fish bone detector for fillets utilizes an intelligent vision and weighing system for fish powered by AI. Instead of relying solely on density, the software analyzes the geometric shape and calcification signature of the object. Since fat lines follow the organic, curved structure of the muscle, the AI can distinguish them from the straight, rigid pin bones, ensuring your salmon pin bone inspection system maintains a high yield.

Why is "Open Frame" 304 stainless steel important for a HACCP compliant salmon processing line?

Hygiene is paramount in a HACCP compliant salmon processing line. An “Open Frame” design using a 304 stainless steel food grade conveyor eliminates hollow tubes and hidden crevices where bacteria like Listeria can thrive. In the salty, wet environment of a salmon plant, 304 stainless steel food grade conveyor materials offer the necessary corrosion resistance to handle brine and fatty acids, while the open architecture ensures that washdown IP69K fish processing equipment can be fully sanitized from every angle.