Introduction

Weight sorting machines play a crucial role in the food processing industry by ensuring precise weight classification and maintaining product consistency. These machines enhance packaging accuracy, minimize waste, and help businesses comply with industry regulations by systematically sorting food items based on their weight.

This article delves into the fundamentals of weight sorting, explores various machine types, examines their benefits and challenges, and highlights their significance across different food sectors.

Key Principles of Weight Sorting

Weight sorting is a vital aspect of food processing, ensuring precision in weight labeling and packaging. By implementing weight sorting technology, food manufacturers can maintain product consistency, meet regulatory standards, and enhance overall efficiency.

Understanding Weight Sorting

Weight sorting in food processing refers to the classification and grading of food products based on their weight to achieve uniformity and quality control. This process is crucial for maintaining product standards, ensuring accurate packaging, and meeting consumer expectations. Weight sorting machines, also known as weight graders or weight sorters, utilize advanced technology to provide precise and reliable weight measurements, enabling manufacturers to achieve consistent product specifications.

Operating Mechanism of Weight Sorting Machines

Weight sorting machines operate using advanced technologies, incorporating sensors, detectors, and automated systems to measure and classify products by weight. As food items move along a conveyor belt, the machine’s sensors detect and record their weight in real time.

Different types of weight sorters may include additional features such as load cells, optical sensors, or electromagnetic detectors to enhance accuracy. The machine’s control unit then compares the recorded weight with predefined criteria and directs products to designated sorting bins or sections accordingly. This fully automated process minimizes human error, improves efficiency, and ensures accurate weight-based classification of food products.

Industries That Utilize Weight Sorting Machines

Weight sorting machines play a crucial role in various food processing industries, ensuring precise weight classification and compliance with quality standards. Below are some key sectors where weight sorting technology is widely applied:

- Seafood Processing: In the seafood industry, weight sorting is essential for categorizing fish and other seafood based on size and weight. This ensures accurate pricing, quality grading, and consistency in packaging.

- Poultry Processing: Poultry products, such as whole chickens or specific cuts like wings and drumsticks, require precise weight sorting for standardized packaging. This process helps meet retail and consumer expectations while improving efficiency.

- Fruit and Vegetable Sorting: Weight sorting machines classify fruits and vegetables based on their weight and size, ensuring uniformity in packaging and presentation. This enhances consumer appeal and optimizes packaging efficiency.

- Chicken Processing: Weight sorting technology is widely used in chicken processing to separate poultry products into specific weight categories. This is crucial for maintaining product consistency and meeting industry standards.

Types and Technologies of Weight Sorting Machines

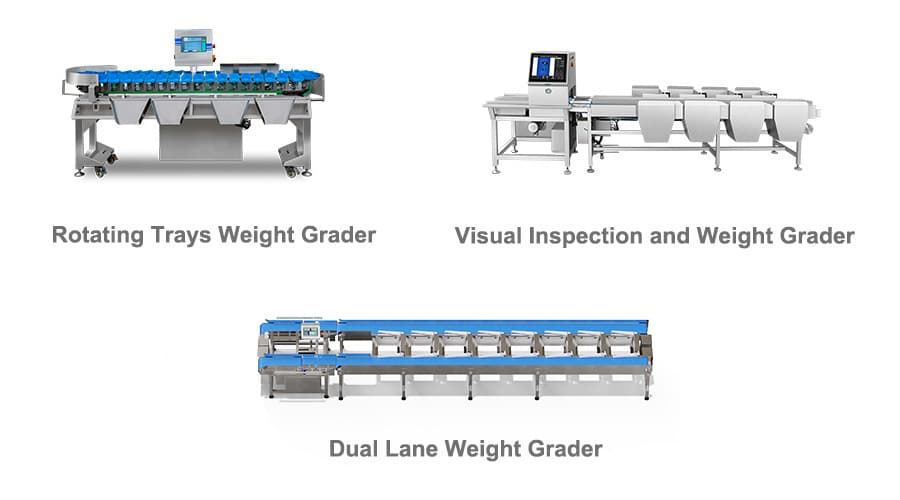

Weight sorting machines come in various designs, each catering to specific industry needs. Below are three common types:

- Dual-Lane Weight Grader: This machine features two parallel sorting lanes, allowing for the simultaneous grading of products. It is ideal for industries with high processing demands, such as seafood and poultry. Each lane is equipped with weight-detecting sensors that can be customized to accommodate different product sizes, ensuring efficiency and flexibility in sorting operations.

- Rotating Tray Weight Grader: This model uses rotating trays to classify products based on weight. Items are placed on the trays, which rotate and tilt to direct them into the appropriate bins or conveyors. This type of grader is especially suitable for delicate products like fruits and vegetables, as the gentle handling mechanism ensures precise sorting without causing damage, thereby preserving product integrity.

- Visual Inspection and Weight Grader: Combining weight sorting with visual inspection, this machine offers a comprehensive quality control solution. Equipped with cameras and sensors, it evaluates both the weight and appearance of products in real time. This dual-function system is particularly beneficial in industries like poultry and fresh produce, where both weight and visual standards must be met for optimal product quality.

Key Components of a Weight Sorting Machine

Weight sorting machines are composed of several essential parts that work together to ensure accurate and efficient sorting. Below are the core components of a typical weight sorter:

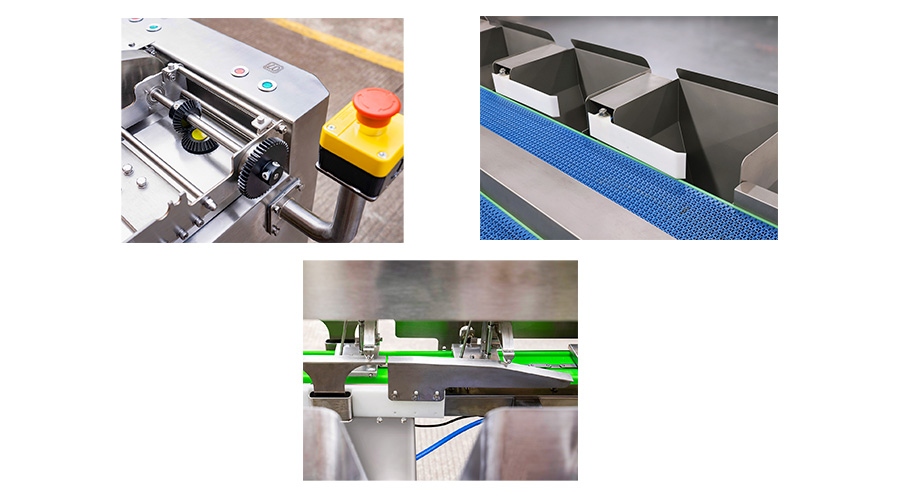

- Sensors and Detectors: These are the fundamental elements of weight sorting machines, responsible for accurately measuring each product’s weight. Common types include load cells, optical sensors, and electromagnetic detectors, all of which provide real-time data to ensure precise and consistent weight classification.

- Conveyor Systems: The conveyor system moves products through the sorting process, ensuring a continuous and efficient workflow. Depending on the application, conveyor designs may include belt conveyors, roller conveyors, or chain conveyors. Many systems offer adjustable speeds and customizable configurations to accommodate different product sizes and weights.

- Control Units: Acting as the central processing unit of the machine, the control system analyzes data from the sensors and detectors to determine how products should be sorted. Advanced software enables operators to set weight categories, define sorting parameters, and monitor performance in real time, ensuring accuracy and operational efficiency.

Benefits and Challenges of Weight Sorting Machines

Weight sorting machines provide significant advantages in food processing by improving efficiency, accuracy, and product consistency. By automating the sorting process, these machines help eliminate common issues associated with manual sorting, such as inconsistency and high labor costs.

Key Benefits of Weight Sorting Machines

- Ensuring Product Quality: Weight grading machines help maintain uniform product quality by precisely measuring and categorizing items based on weight. This consistency is essential for meeting industry standards and consumer expectations, ultimately enhancing brand reputation.

- Boosting Operational Efficiency: Automated weight sorting significantly increases processing speed, handling large product volumes faster and more accurately than manual sorting. This improvement enhances overall productivity, allowing manufacturers to meet production targets and fulfill large orders efficiently.

- Minimizing Waste: By accurately sorting products into designated weight categories, these machines help reduce material waste and prevent packaging inconsistencies. Proper weight distribution ensures that products are neither overfilled nor underfilled, optimizing resource utilization.

- Enhancing Customer Satisfaction: Consistency in product weight and quality plays a vital role in customer satisfaction. Automated weight sorting ensures that consumers receive uniform products that meet their expectations, building trust, brand loyalty, and repeat purchases.

Challenges of Automatic Sorting Machines

While automatic sorting machines offer numerous benefits to the food processing industry, they also present certain challenges. Here are some key obstacles faced by businesses:

- Accuracy and Technical Issues: Ensuring precise sorting remains one of the main challenges in using automatic machines. Variations in product shape, texture, and composition can sometimes affect weight measurements. Irregularly shaped items, for example, may not align properly on conveyor belts, leading to inaccurate readings. Additionally, environmental factors such as temperature and humidity can impact sensor performance and other components, potentially compromising the system’s overall accuracy.

- Financial Investment: The upfront cost of automatic sorting machines can be significant, presenting a financial challenge for smaller businesses. These machines often require a large initial investment for purchase, installation, and integration into existing production systems. In addition, ongoing expenses related to operation, maintenance, and occasional system upgrades can add to the financial burden.

- Maintenance and Calibration Demands: Regular maintenance and calibration are vital for the smooth operation and longevity of weight sorting machines. As complex systems with numerous mechanical and electronic parts, these machines are subject to wear and tear over time. Routine servicing is essential to prevent breakdowns and ensure consistent, accurate performance.

Conclusion

Weight sorting machines have become an integral part of modern food processing, playing a key role in streamlining the product weight grading process. These machines provide notable advantages, including enhanced quality assurance, increased operational efficiency, and reduced waste. While they do present challenges, particularly regarding their financial cost, the benefits they offer far outweigh these concerns. As a result, weight sorting machines remain a valuable and indispensable asset in the food processing industry.